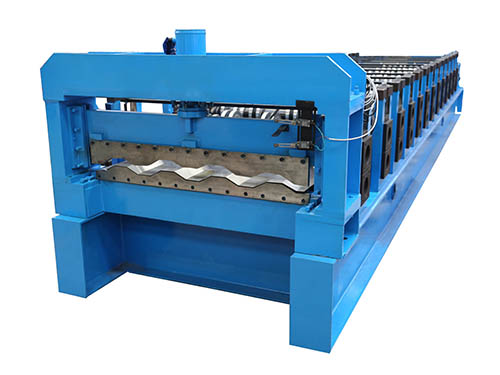

Basic Info Model No.:JCX_1075 Tile Type:Colored Steel Certification:SGS,CE,ISO Condition:New Customized:Customized Usage:Floor Transmission Method:Electric Main Power Of Machine:11kw Two Sets Speed Of Machine:12-15meters Per Minute Color Of Machine:Blue Or As Your Request Voltage Of Machine:380v,50hz,or As Your Request Material Of Rollers:S45C With Heat

Basic Info

Model No.:ZD_1075

Tile Type:Colored Steel

Certification:SGS,CE,ISO

Condition:New

Customized:Customized

Usage:Floor

Transmission Method:Electric

Main Power Of Machine:11kw Two Sets

Speed Of Machine:12-15meters Per Minute

Color Of Machine:Blue Or As Your Request

Voltage Of Machine:380v,50hz,or As Your Request

Material Of Rollers:S45C With Heat Treatment

Material Of Cutting:Cr12 Hrc58-60

Structure Of Machine:400H Beam

Material To Roll Forming:1-2mm

Diameter Of Shaft:100mm

Sizes Of Chain:Double 1.2inch

Additional Info

Packaging:standard overseas packing

Productivity:10sets/Months

Transportation:Ocean,Land

Place of Origin:Hebei,China

Supply Ability:10sets/Months

Certificate:CE,ISO9001

HS Code:84552210

Port:Tianjin

Product Description

Newly durable ship container panel roll formirng machine

The Newly durable ship container Panel Roll Forming Machine is designed for production of metal car panels with different designs.normally thickness is from 1–2mm in ranges.It’s made of Undecoiler_main forming machine_control system_cutting system_hydraulic system.

Fully automatic line is easy to operate!

1.Material thickness:1-2mm

2.Process flow:Decoiling–feeding—forming—cutting—production

3.Manual Decoiler:

3.1 Material coil inner diameter:450mm-700mm

3.2 Max coil width:1200mm

3.3 Carrying capacity:5T

4.Forming Device:

4.1 Number of forming steps:22 steps

4.2 Shaft material:45#steel with harden treatment,outer diameter 100mm

4.3 Roller material:45#steel

4.4 Main motor power:2*11kw

4.5 Forming speed:8-10m/min

4.6 Voltage:380V/50Hz/3 phase

5.Cutting Device:

5.1 hydraulic cutter

5.2 blade,puncher and mold material:Cr12 steel with quenched treated 60-62C

5.3 cutting system:Advanced hydraulic drive,automatic cutting after forming,no distorting or wasting,high level safety factor.

6.Controlling Device:

6.1 Screen:5.7 inch Delta screen from Taiwan

6.2 PLC:Delta DVP14ES from Taiwan

6.3 coder:Japanese Omron E6C2

7.Hydraulic:

7.1 Advanced hydraulic system from Taiwan

7.2 Power:2*11+5.5 kw